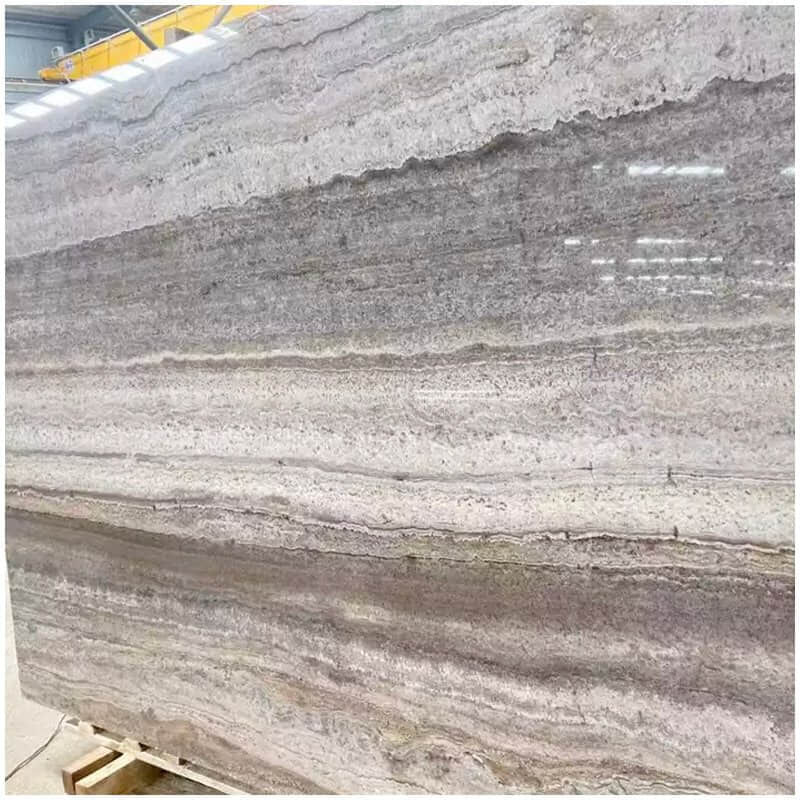

sintered countertops

Sintered countertops represent a revolutionary advancement in surface technology, combining natural minerals and cutting-edge manufacturing processes to create extraordinarily durable and versatile surfaces. These countertops are manufactured through a sophisticated sintering process that subjects raw materials to extreme pressure and temperatures exceeding 1200°C, effectively replicating the natural stone formation process but in a fraction of the time. The result is a highly compact, non-porous surface that exhibits remarkable strength and resistance to various forms of damage. These countertops boast exceptional resistance to scratches, stains, UV rays, and extreme temperatures, making them ideal for both indoor and outdoor applications. Their non-porous nature ensures zero liquid absorption, preventing bacterial growth and making them incredibly hygienic for food preparation areas. The manufacturing process allows for the creation of large-format slabs with consistent patterns and colors, offering designers and homeowners unprecedented aesthetic flexibility. These surfaces can be manufactured in various thicknesses, typically ranging from 6mm to 20mm, accommodating different application requirements while maintaining their superior technical properties.