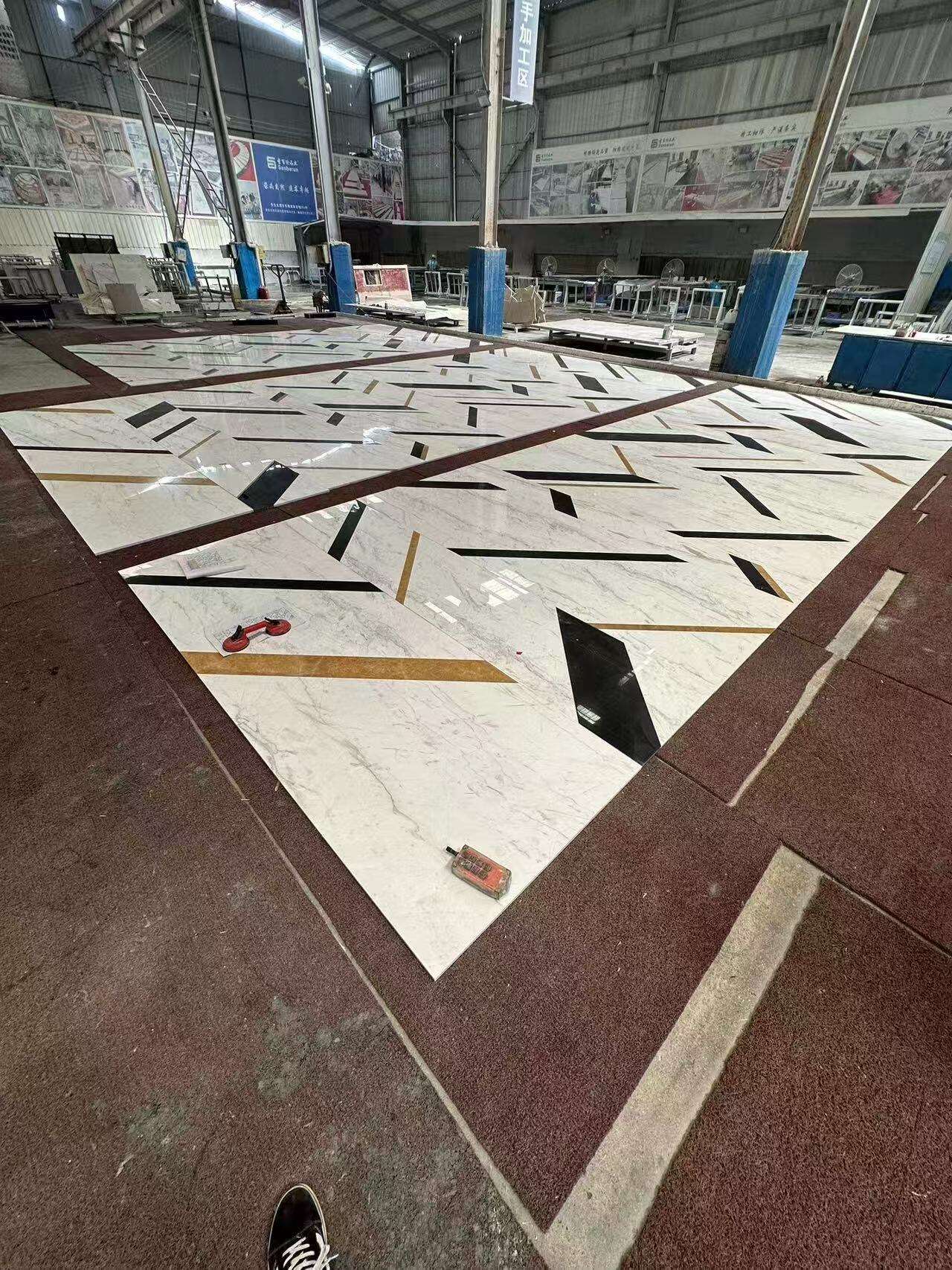

marble waterjet

The marble waterjet represents a cutting-edge technological solution in stone processing, combining precision engineering with powerful water pressure to achieve exceptional cutting results. This sophisticated system utilizes a high-pressure stream of water mixed with abrasive particles, typically garnet, to cut through marble with remarkable accuracy and efficiency. Operating at pressures up to 60,000 PSI, the waterjet creates clean, precise cuts without generating heat, eliminating the risk of thermal damage to the material. The system's advanced computer numerical control (CNC) ensures precise positioning and movement, allowing for complex patterns and intricate designs to be executed with minimal material waste. The marble waterjet can handle materials of varying thickness, from thin decorative pieces to substantial slabs, making it versatile for different applications. Its cutting capabilities extend beyond straight lines to include curves, angles, and detailed patterns, essential for architectural elements, custom designs, and artistic installations. The technology's environmental consciousness is evident in its water recycling systems and minimal dust production, making it a sustainable choice for modern stone processing facilities.