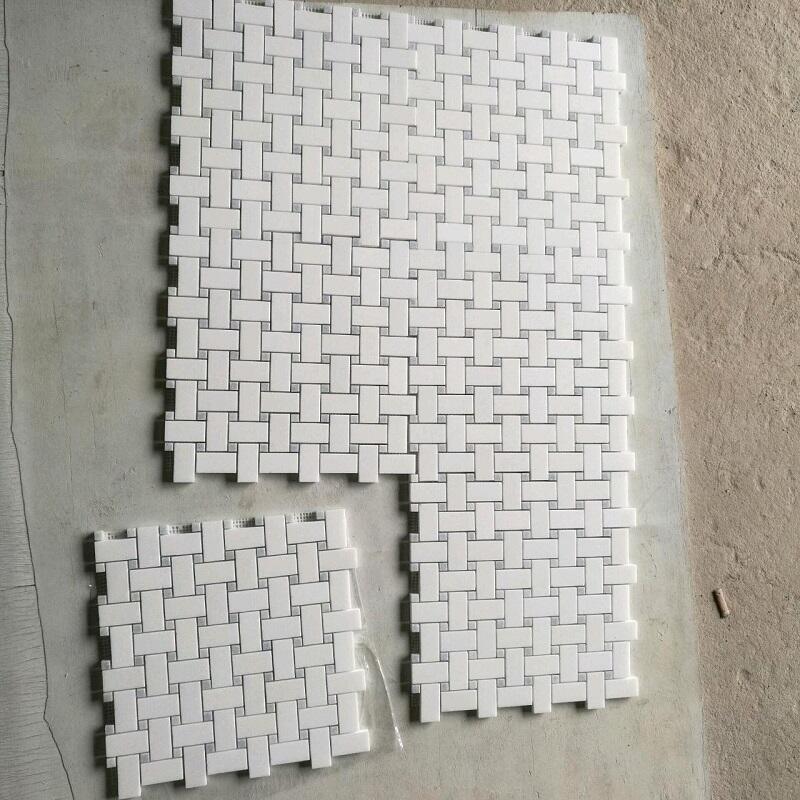

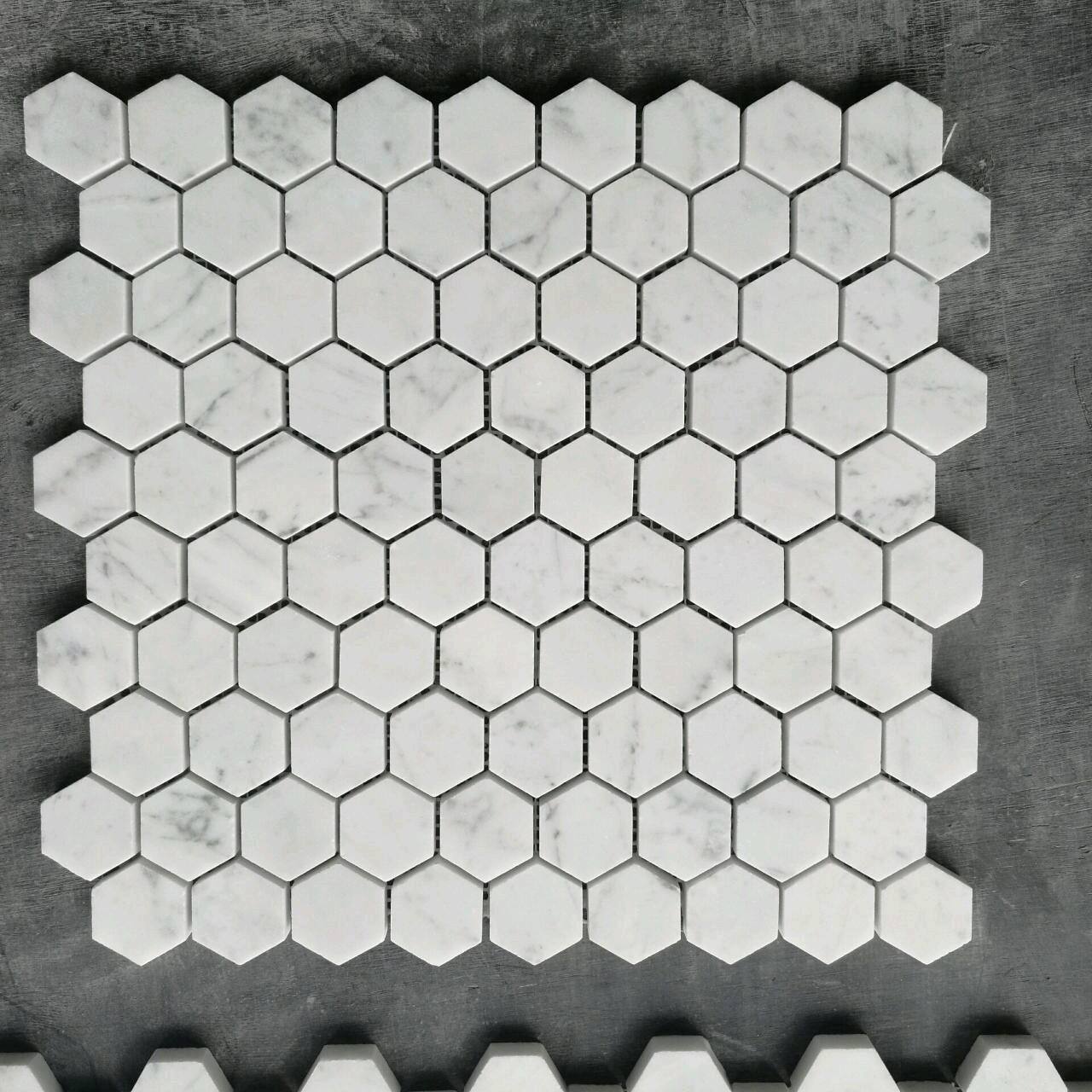

vesijet marmori mozaïikkeraamik

Voolupõrandad marmormozaïkkivid esindavad täpsuse käsituskunsti tippu kaasaegses sisearhitektuuris. Need imelikud kiud valmistatakse edasppideval tootmismeetodil, mis kasutab kõrgtöömelist voolupõrandat, et lõigata keerulisi kujundeid ja disainisid loodusmarmorki. Tehnoloogia võimaldab ebatavalist täpsust keeruliste kujundite ja kujuplaanide lõiguks, mis tagab plokide vahelise sidususe. Tootmise protsess kombineerib traditsioonilisi marmori töötlemismeetodeid kaasaegse voolupõrandatehnoloogiaga, mis võimaldab luua sofistikateid disainisid, mida ei ole võimalik saavutada traditsiooniliste lõikamismeetodite abil. Need mozaïkkivid on eriti hinnatud luxushuvitistes ja äriobjektides, pakudes erakordset disainipoliitikat samal ajal, kui säilitab marmori loomuliku ilu. Kiude saab kohandada erinevate kujundite loomiseks, alates geomeetrilistest disainidest ning lõpetades virtuaalse kunstiga kooskõlastuvate kompositsioonidega, mis teeb iga installatsiooni unikaalseks. Voolupõrandalõigu protsess tagab minimaalse materjalihaste ja säilitab marmori struktuuri, vältides mikrofraktuure, mis võivad tekkitada traditsiooniliste lõikamismeetodite korral. See edasppidev tootmetehnoloogia võimaldab ka sama mozaïkkujundi raames erinevate marmoritüüpide ja -värvide kombinatsioone, mis loovad imelikke visuaalseid efekte, mis suurendavad igas ruumis.