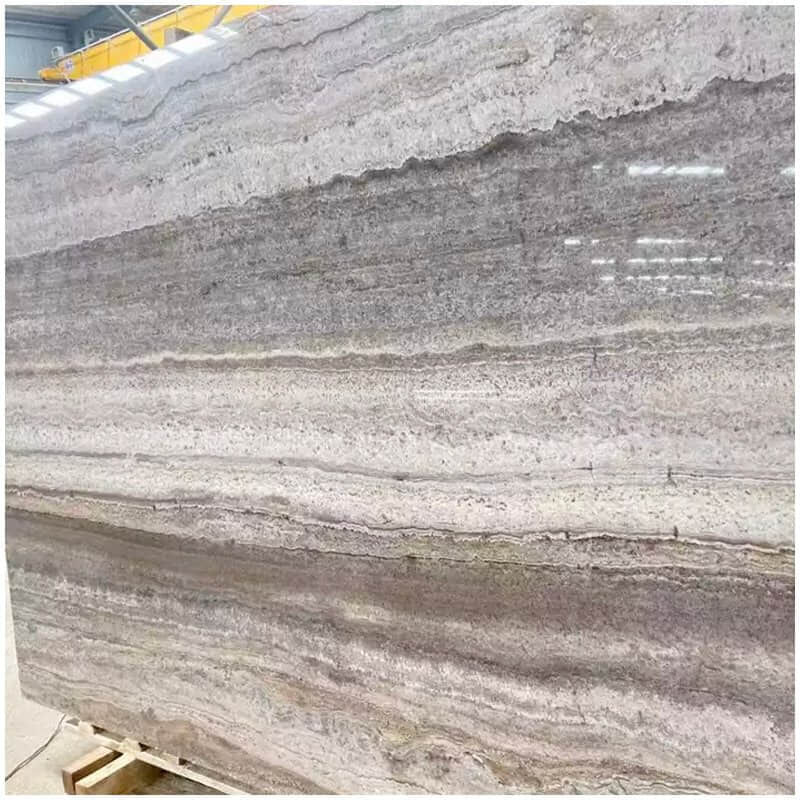

sintered stone material

Ang sintered stone ay nagrerepresenta ng isang mapanaginip na pag-unlad sa mga nilikha na ibabaw, nilikha sa pamamagitan ng isang maagang proseso na kumokopya sa natural na pormasyon ng bato sa loob ng mga libong taon, ngunit natatapos lamang sa ilang oras. Gawaing ito ng matinding anyo ay ginawa sa pamamagitan ng paglalapat ng minerales at pangunahing sangkap na maingatan sa ekstremong init at presyon, humihudyat ng isang napakadinsay at mabilis na ibabaw. Ang proseso ng sintering ay nagbabago ng mga pangunahing sangkap sa temperatura na humahabol sa higit sa 1200°C, lumilikha ng molecular na mga bond na nagbibigay ng isang hindi porosong, mabuting resistant na anyo. Ang huling produkto ay nag-uugnay ng eksepsiyonal na teknikal na katangian kasama ang kamangha-manghang estetikong kagandahan. Nagpapakita ang sintered stone ng kamangha-manghang resistance sa mga sugat, sunog, UV rays, at ekstremong temperatura, gumagawa nito ng isang ideal na pagpipilian para sa iba't ibang aplikasyon. Ang kanyang kakayahang mag-extend ay mula sa panloob na aplikasyon tulad ng kitchen countertops, bathroom vanities, at flooring hanggang sa panlabas na gamit tulad ng building facades at outdoor kitchen surfaces. Ang malapit na sero na porosity ng anyo ay nagpapatakbo na mananatiling hindi nakakapasok sa mga likido at resistant sa paglago ng bakterya, gumagawa nito ng partikular na maayos para sa mga lugar ng paghahanda ng pagkain at medikal na mga facilidad. Ang advanced na mga teknika ng paggawa ay nagpapahintulot sa paglikha ng malaking format na panels na may minimum na kapal, nagbibigay ng hindi karaniwang kreatibong kalayaan sa mga arkitekto at disenyer habang patuloy na pinapanatili ang integridad ng estruktura.