larg dhe larg me ujë

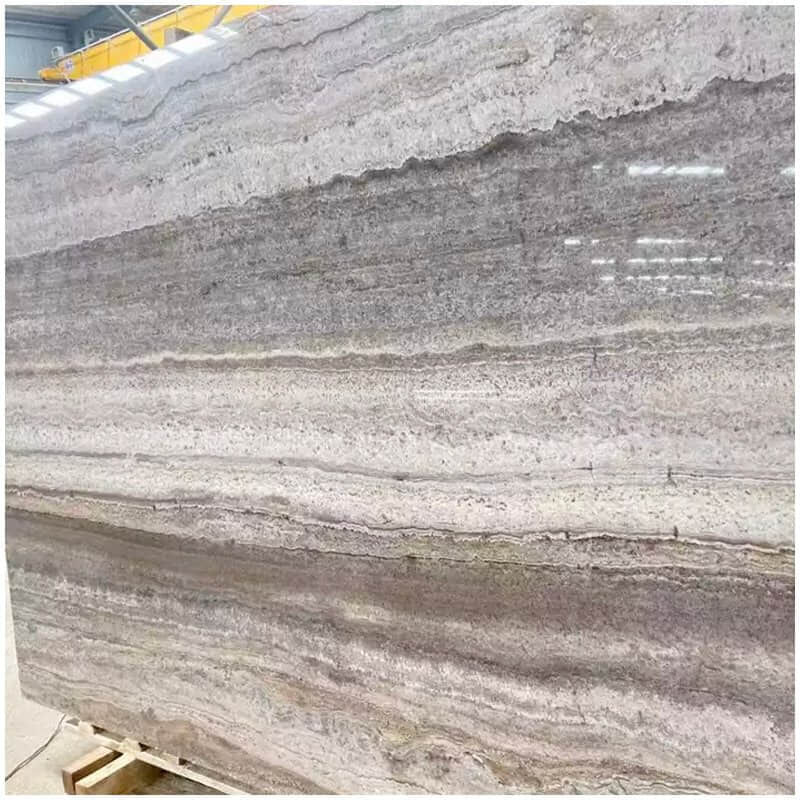

Largimi i marmirit me ujë përfaqëson një teknikë sofistikuar të fabricimit të gurit që përbãn ketë prezhion dhe inxhinieri me konscienca mjedisore. Kjo metodë e parjeve të avancuara përdor jetet e largta të ujës në shtresë të largta me partikula abrasivë për të larguar marmirin me akuracijë e ulët. Procesi përfshin drejtimin e një rrymës koncentruar të ujës, zakonisht të preshur deri në 60.000 PSI ose më shumë, nëpër një sistem specifik të duzeve. Kur jeti i ujës plotëson sipërfaqen e marmirit, krijon një largim të akurat dhe në të njëjtën kohë hollon materialin dhe largon larg detritet. Kjo teknologji është veçanërisht vlerësuar në aplikime arhitektonike, punime personalizuara të gurit dhe projekte artistike të detajuara ku akuracja është e parëndryshme. Largimi i kontrolluar nga kompjuteri i sistemit siguron kualitet të njëjtë të largimeve në pattern dhe dizajne komplekse, ndërsa procesi i hollave me ujë mbahen larg stresin e lidhur me largimin e ftohtë që mund të dëmtonte gurin. Përmes kësaj, kjo metodë e largimit e përmbush gjatësinë të ndryshme të marmirit dhe mund të ekzekutojë dizajne të ndjeshme që do të ishin ndjenjë apo jo e mundur me metodat tradicionale të largimit. Integrimi i teknologjisë CAD/CAM lejon riprodhimin e akurat të dizajneve dhe patterneve, bënjë e ideal për prodhim masiv dhe projektet personalizuara. Më tepër, procesi i bazuar në ujë minimizon prodhimin e larg dhe krijon një ambient punës më sigur duke larguar nevojën për pastrojtje.