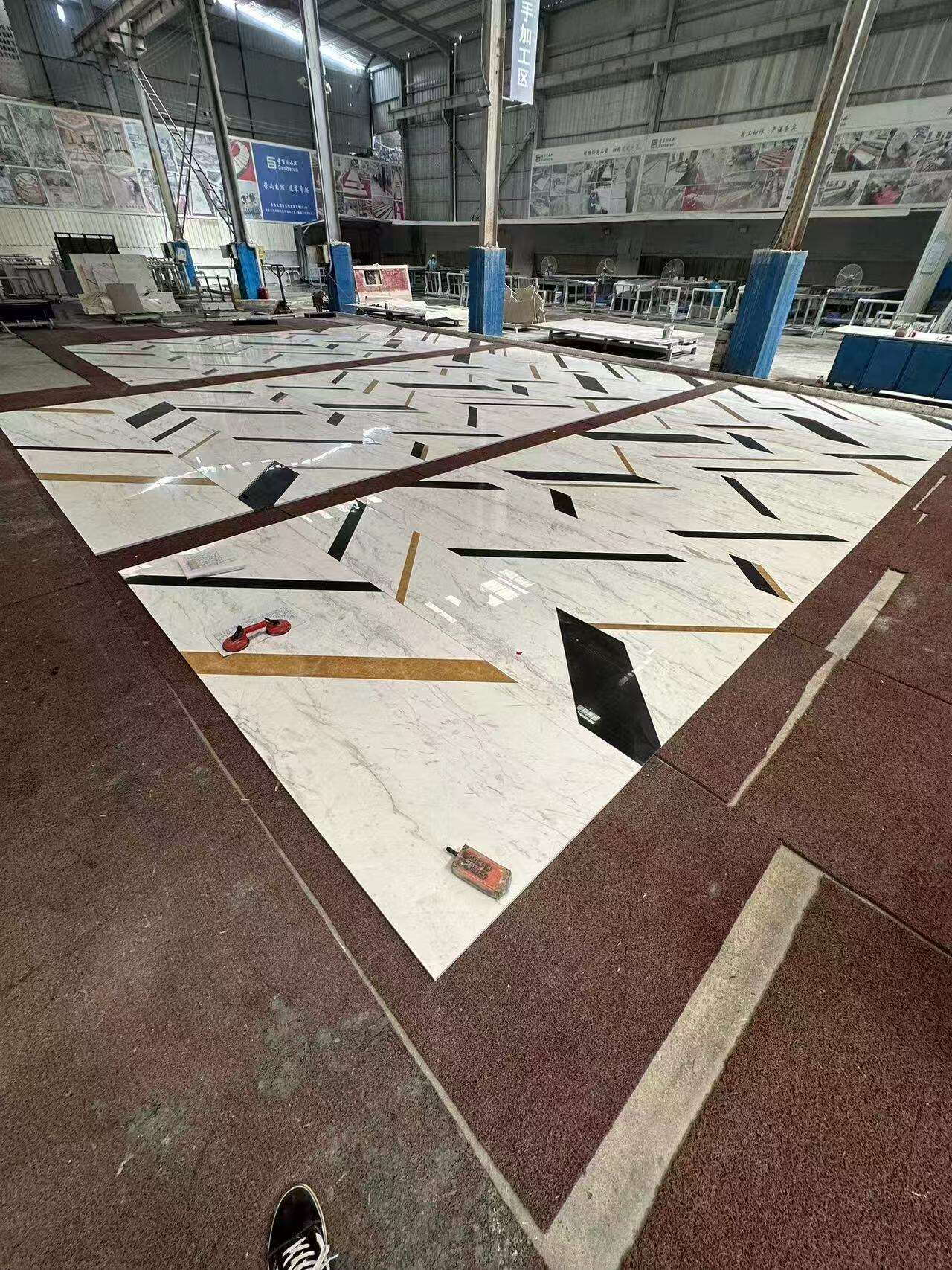

vodačepno rezanje mramora

Vreženje mramora z vodo s pomočjo hidrauličnega strelnika predstavlja najnovejšo tehnološko rešitev za obdelavo kamna, ki uporablja visoko pritiskano vodo, smesano z odtrgavalnimi delci, da natančno preseče mramor z užasajočo natančnostjo. Ta napredna metoda vrezanja deluje tako, da pospešuje usmerjen tok vode pri pritiskih do 60.000 PSI, povečan s granatnimi odtrgavljivi, da doseže čist in natančen rez na površinah mramora. Tehnologija se izjemno izkazuje pri ustvarjanju zapletenih vzorcev, složenih oblik in prilagojenih oblik, hkrati ohranjajo strukturno celovitost mramora. Postopek je računalniško nadzorovan prek sistemov CAD/CAM, kar zagotavlja izjemno natančnost in ponovljivost vsakega reza. Ta najnovejša tehnologija ima široko uporabo v arhitektonskih elementih, dekorativnih delih, podlahnih vgradbah in prilagojenih namestitvah mramora. Versatilnost sistema omogoča obdelavo različnih debeline in vrst mramora, od jemanj večinjenih variant do gostih, kompaktnih kameni. Zlasti hladno vreženje izključi območja, ki so ogrožena zaradi toplega procesa, preprečuje toplinski stres in morebitne poškodbe materiala. Natančnost in versatilnost tehnologije jo dela nesremenjivo v komercialnih in umetniških aplikacijah, omogočajoč ustvarjanje vsega od praktičnih arhitektonskih komponent do zapletenih dekorativnih del.