gwaith marbl melyn carrara

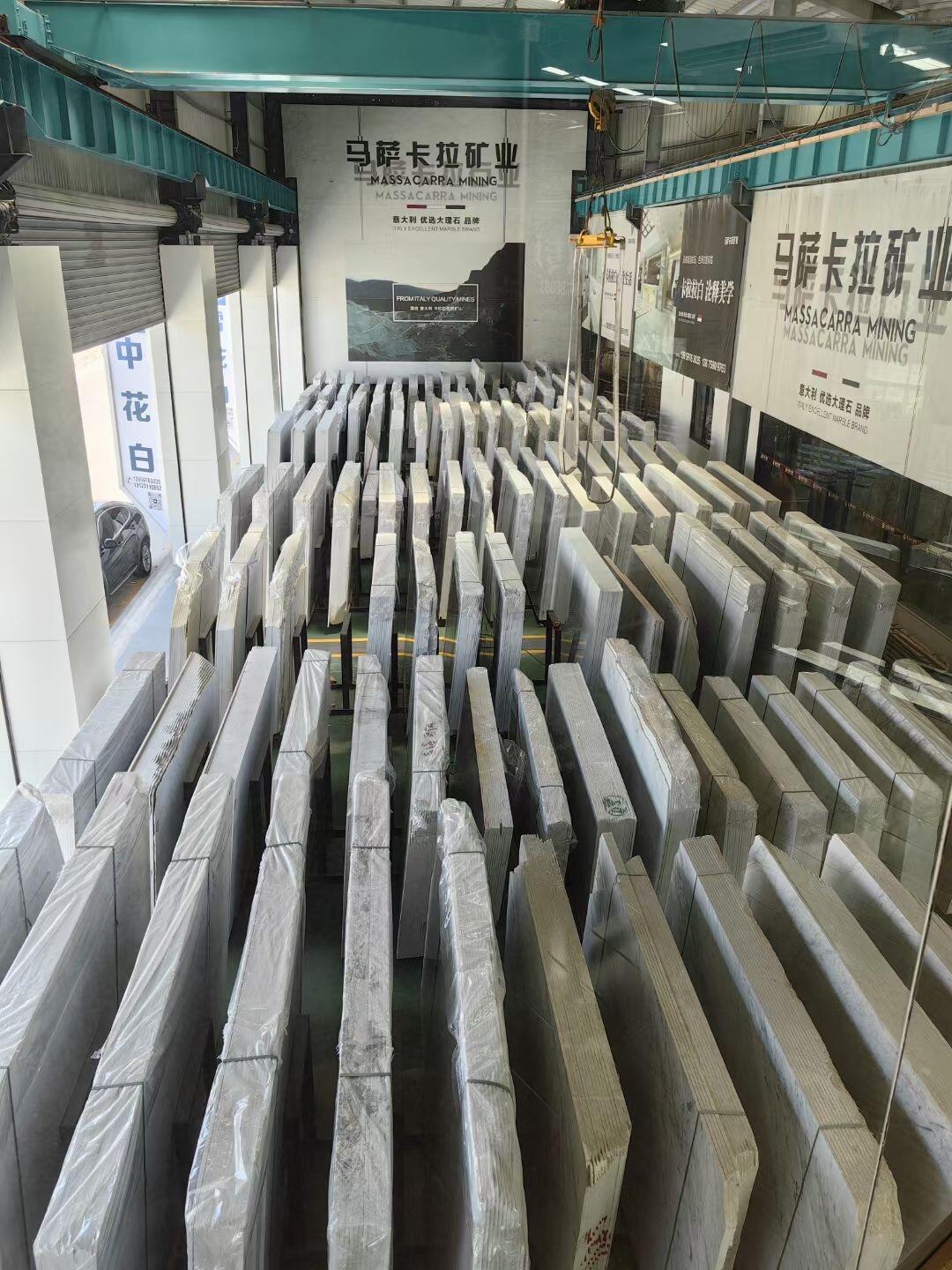

Mae Llwyfan Marmor Gwyn Carrara yn lleoliad cynhyrchu brif a dedwydd sy'n addasol i brosesu a chynhyrchu'r marmor gwyn gorau sydd wedi'i ddal o'r ardal dylanwadol o Gerara, Yr Eidal. Mae'r lleoliad hwn gyda thechnoleg modern yn cyfuno â phrofiadau canfyddol o ganfyddion canolig i greu cynnyrch marmor arbennig. Mae'r lleoliad yn gweithredu llines cynhyrchu llawer sydd eu harferiad â chynghorion CNC uchel, systemau tocynu awtomatig, a threwyn polio preswyl sy'n gallu brosesu blociau marmor fawr i wahanol cynnyrch wedi'u gwblhau. Mae'r cyapasadwyedd cynhyrchu'r lleoliad yn mynd i'r wyneb 50,000 metr sgwâr bob mis, gyda phrosesau gan gynnwys tocynu clod, cynhyrchu tiwl, elfennau architecwl cymarebol, a thrawsgrifiadau siofal arbennig. Mae systemau rheoli ansawdd yn defnyddio thechnoleg delwed digidol a tharchnoleg analu safleol i sicrhau cysondeb mewn lliw, llinellu, a thrwm ar draws pob cynnyrch. Mae'r lleoliad hefyd yn cynhwys storfa cadw raddfa climaidd o faint 15,000 metr sgwâr, sy'n dodwain materion gymhlyg a chynnyrch wedi'u gwblhau. Mae ystyriadau amgylcheddol yn cael eu cyfuno i'w gweithrediadau drwy drefnu systemau aildefnyddu dŵr, mecanismau casglu tos, a thechnoleg prosesu effeithlon-energi. Mae'r lleoliad hefyd yn cynnwys canolfan logisteg sophistigedig ar gyfer anfon byd-eang a chanolfan profi cleientiaid lle gall cleientiaid dewis eu materion personol a drafod opsiynau cyfnewid.